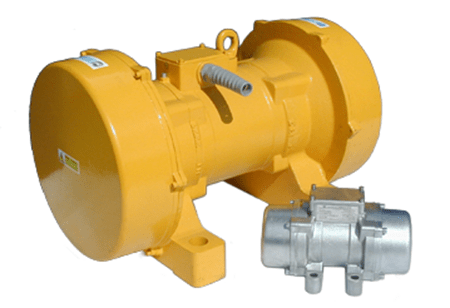

VIBRATOR MOTORS

Types of machines

Basic information

The principle of surface vibrators

What is the surface vibrator ?

In fact it is the source of rotating force consisting of:

- integrated electromotor with reduced power output

- shaft of motor which is prolonged on both sides

- unbalanced counterweights fixed on the shaft ends and covered by shields

- flanged vibrator body, in which are stator and shaft bearings.

Centrifugal force

It appears when mass body (in our case unbalanced elements) starts to rotate around axis of rotation when the gravity center is not situated on this axis. The extent of the force is given by:

- static momentum of the unbalanced counterweights

- square of the rotation (frequency)

Static momentum of the unbalanced counterweights

Basically it is the product of:

- the mass of counterweight and

- the distance of the center of its gravity center from axis of rotation

The measure unit is kg.mm.

The value given in the vibrator property sheet is the sum of static momentum of all (four) counterweights when adjusted to 100% effect.

The working momentum of the unbalanced counterweights

Double value of the static momentum is usually given as vibrator property in German speaking countries. It is because a peak-to-peak amplitude is being applied in this region while we use only single amplitude value.

What is the main feature of the vibrator ?

Revolutions and a maximum centrifugal force, which is vibrator able to reach. The power input is not an important factor. The centrifugal force is not unique identificator and we cannot be sure if the momentum of the unbalanced counterweights is static or working (see above).

Do you need to replace your current vibrator ?

Kindly refer to us and we will suggest an option for replacement. Ideally, when a machine plate is readable, we must get some information from the following list:

- manufacturer and a type of the vibrator. We have catalogues of mostly produced vibrators and then we can find up properties of the vibrator and suggest replacement,

- rpm and centrifugal force, which is given in N, kN, daN (which is decanewton unit, former kilopond, which is imaginable as “kilogram”),

- revolutions (rpm - rounds per minute) and its static (or working) momentum, or briefly something with units as kg.mm, or kg.cm .

If you do not want to study the machine plate, take a picture and send it to us. Do not bother if the plate is missing. Revolutions are measurable and the counterweight is possible to draw on paper and we can estimate its properties.

Applications of surface vibrators

Shaking/knocking the hoppers

Having a storage tank or silo or feeder with a small slant and your material is not loosing as you wish? Then application of surface vibrator for shaking solve such problem in most cases!

- the vibrators with working frequency 50Hz (3000rpm) are used

- we will suggest the power of the vibrator according to size of the hopper and thickness of its wall

- the mounting place for the vibrator is better to reinforce, the clamps then may be used for mounting the vibrator

- the vibrator is not running permanent, it is usually switched on in regular periods

The drive of the machines and equipment

How many vibrators and where to implement them ?

- vibrator for knocking is enough one, usually it is mounted in the lower third of a cone part of the hopper, we will recommend you the proper size,

- the vibrators for the machine drive is the exclusive task for the machine designer

Unbalanced counterweights adjustment

When required, the size of centrifugal force and thus the amplitude of oscillation is possible to change by adjustment of the unbalanced eccentric counterweights.

- you will do it by changing the angle position of the adjustable internal element against the fixed external one,

- for its adjustment it is necessary to loose the grip screw of the internal element,

- the value of the centrifugal force is expressed as a percentage of the maximum centrifugal force and results comparing coloured edge of the adjustable element with the scale on the fixed counterweight,

- the position of the counterweights on the both shaft ends of one vibrator must be the same, if two vibrators are used on one machine, their adjustment must be identical.

The basic rules for the mounting

Bearing surface under vibrator`s flanges

- must be flat (across all four seating spots) with maximum deviation 0.2 mm

- roughness Ra 6.3 up to 12.5

- surface of the flanges and under them must be clean to metal, with removed color, grease and other impurities

Elements of screw coupling

We recommend following combination:

- screw ISO 4014 8.8 – must be strength resistant !

- flat washer ISO 7090

- stop bolt nut ISO 7040 8 (with plastic inlay)

Warning:

- we recommend to use longer screws, which correspond better to dynamic character of stress in the coupling

- in case of dismantling new bolt nuts must be used

Tightening moment

The bold nut of the coupling must be tightened by momentum key according up to indicated values according to following table:

| Nominal thread [Nz] | Tightening moment [N.m] |

| M 6 | 9,7 |

| M 8 | 24,5 |

| M 10 | 48,4 |

| M 12 | 84 |

| M 16 | 209 |

| M 20 | 406 |

| M 24 | 699 |

| M 30 | 1408 |

| M 33 | 1914 |

| M 36 | 2456 |

Periodic control of tightening

Tightening of the vibrator is necessary to check after 1, 8, 100 and then after each 300 running hours (especially when applied on vibratory machines) according to manual and technical specifications for use of vibrator and machine. The same must be executed when you replace the vibratory drive unit with another one.

Technical features

What is the difference between type AO and AA?!

From the user’s point of view is none.

We have decided to use these marks to follow the previous line and description of VO and VA line. The difference is in the construction of the body casing and for the end user is not significant.

- AO - the vibrator body is cast as one piece

- AA - the body is composed of two main pieces: of the shell with integrated stator and of the bearing brackets with flanges , used for bearing mounting and coupling the drive unit.

What is the type FO ?

It is a special construction of selected NO vibrators that enables to run it up to 6000 rpm (which responds to working frequency 100Hz). Vibrator itself cannot reach such RPM level - it must be used together with frequency converter!.

Vibrator revolutions

For various purpose of use different operating frequency is necessary! Usual operating frequency corresponds to rounds-per-minute value of asynchronous electromotor:

| Frequency [Hz] | RPM [1/min] | Construction of motor | Example of VIBROS vibrator |

| 12 | 750 | eight poles | NO28 |

| 16 | 1000 | six poles | NO26 |

| 24 | 1500 | four poles | NO24 |

| 50 | 3000 | two poles | NO22 |

| 100 | 6000 | (with frequency inverter) | FO22 |

Take note - the last digit in our vibrator name gives the number of poles of electric motor.

Input voltage

The standard execution of vibrators is for voltage input 3x400 AC. Different execution on customer’s demand is available also for another three-phase systems. Recently we do not produce vibrators for 1x230V AC, 12 and 24V DC.

Input voltage frequency

Standard design is for input frequency 50 Hz. All technical specifications indicated in description sheets are stated for this working frequency. A construction on demand is possible also for 60 Hz frequency.

Mechanical protection

Mechanical protection IP65 according to CSN EN 6034-5. In other words, it does not matter, if vibrator is exposed to rain. There are not ventilation slots as on usual electromotor, thus no water can leak inside.

Conformity for operation in explosive atmosphere

Our produced vibrators are not designed for applications in explosive atmosphere (exclusive special construction of vibrator NA66). Nevertheless, we are able to arrange supply of vibrator with such certification to you.

Insulation class

Vibrators are produced in the temperature class “F” according to CSN 33 0250.

PTC thermistor for thermal protection

On customer’s demand we can arrange our vibrators with thermistors implemented on coil winding for detecting high temperature.

The need of PTC thermistor rises in case of vibratory control by frequency converter (and is often demanded by customers in such case). Usual electromotor is decreasing cooling intensity with decreasing rpm. Our surface vibrators have no cooling, and on the opposite, their protection is IP65, thus the use of PTC thermistor protection is disputable. Anyway, when requested, we satisfy the customer’s demand.

Surface finish

Standard paint coating is done by synthetic color S2029 in yellow color shade 6401. If requested, we can arrange another shade or color finish, e.g. applicable in food industry.

Braking the vibratory rundown

Why is it necessary to brake?

The working frequency of the most of vibrating machines driven by surface vibrators is usually high above their own resonance frequency. During slow rundown of the machine, when the frequency of vibrators meets this machine own resonance the oscillation amplitude will reach several times higher value for few seconds. This phenomenon is not acceptable both for various applications and machines, but it may be eliminated by shortening the rundown time.

Which machines should we brake ?

It is suitable to brake all over-resonance machines. However, the brake is necessary for following machine groups:

- all types of feeders and conveyers, which charge substances to the scales - when the brake is not applied here, an uncontrolled overcharging can occur

- heavy and big machines - the application of brake system may prevent damage of the springs or even the complete machine

- machine with dustproof shields – there is danger of damage of hermetic sealing elements

How to brake ?

For elimination of higher dynamic effects during the rundown of the machine a d.c. brake block is being utilized.

The coil winding of the stator (one of its phase) is connected to direct current. Such magnetic field does not rotate and induced magnetic field in rotor cause to run-down within few (1-2) seconds. We supply an electronic element to activate this process - d.c. converter DCBB (BSB). Wiring circuit must be realized according to circuit scheme (next switch and time-relay are necessary). We can supply also switchboard case for the vibratory machine, which will include the DCBB with appropriate wiring.

VIBROS s.r.o.

Address:

Ke Skalám 651

261 01 Příbram

Company info:

Id.No.: 61683850

V.A.T. Id. No.: CZ61683850